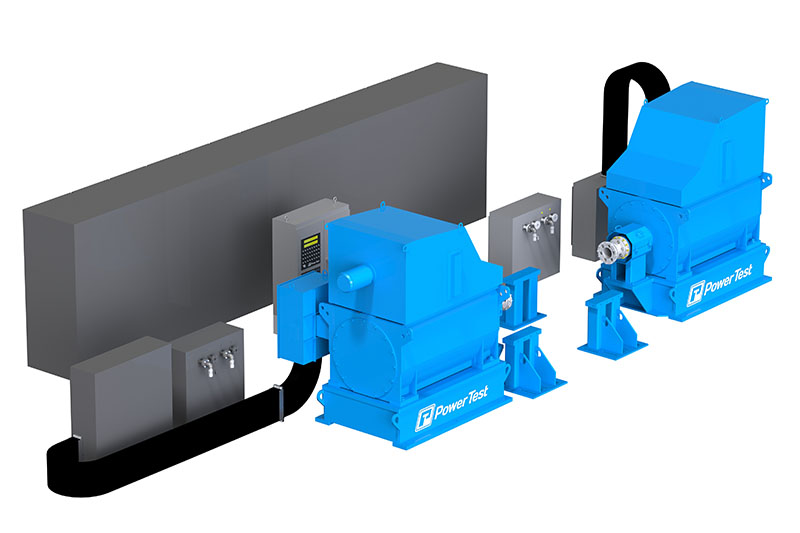

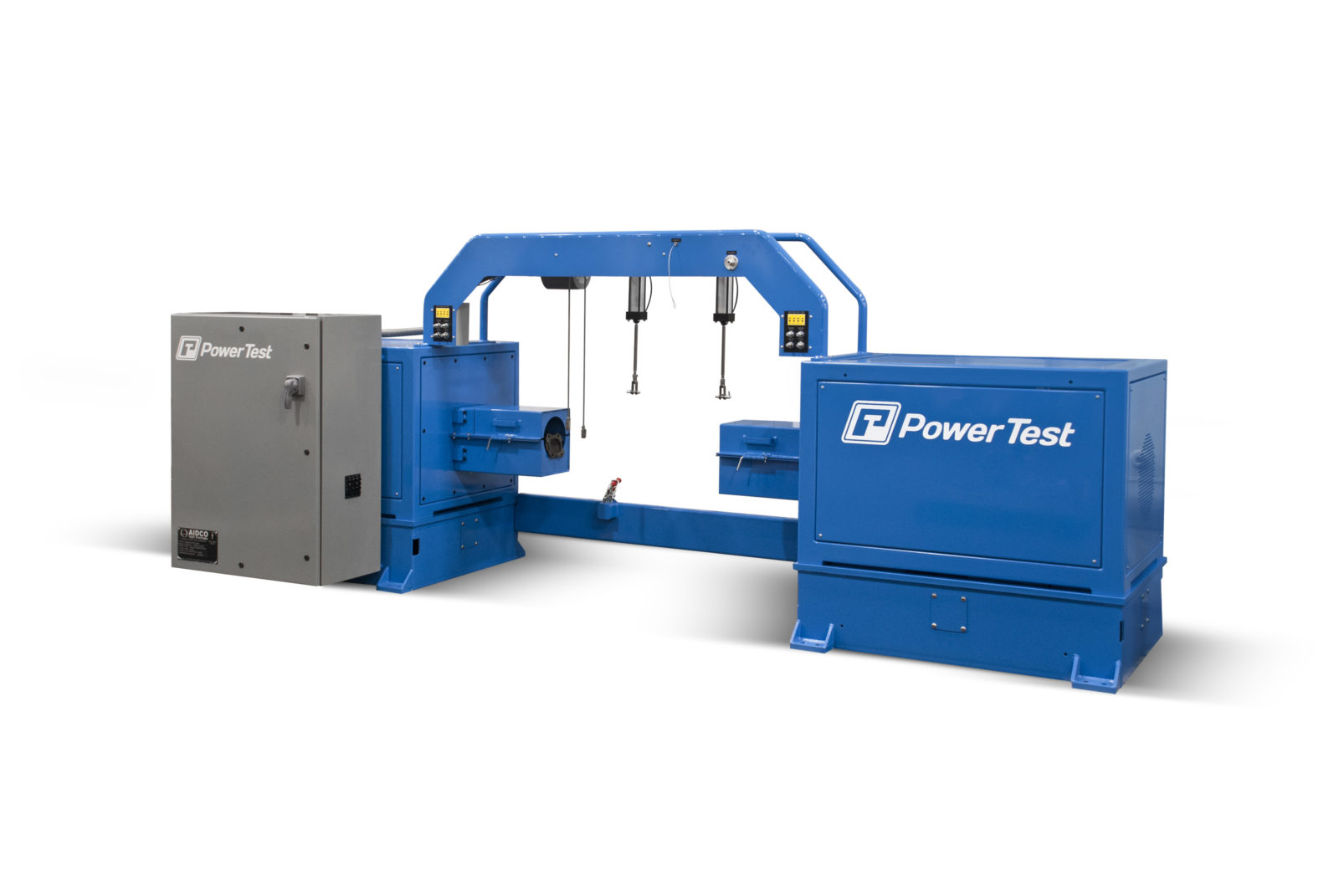

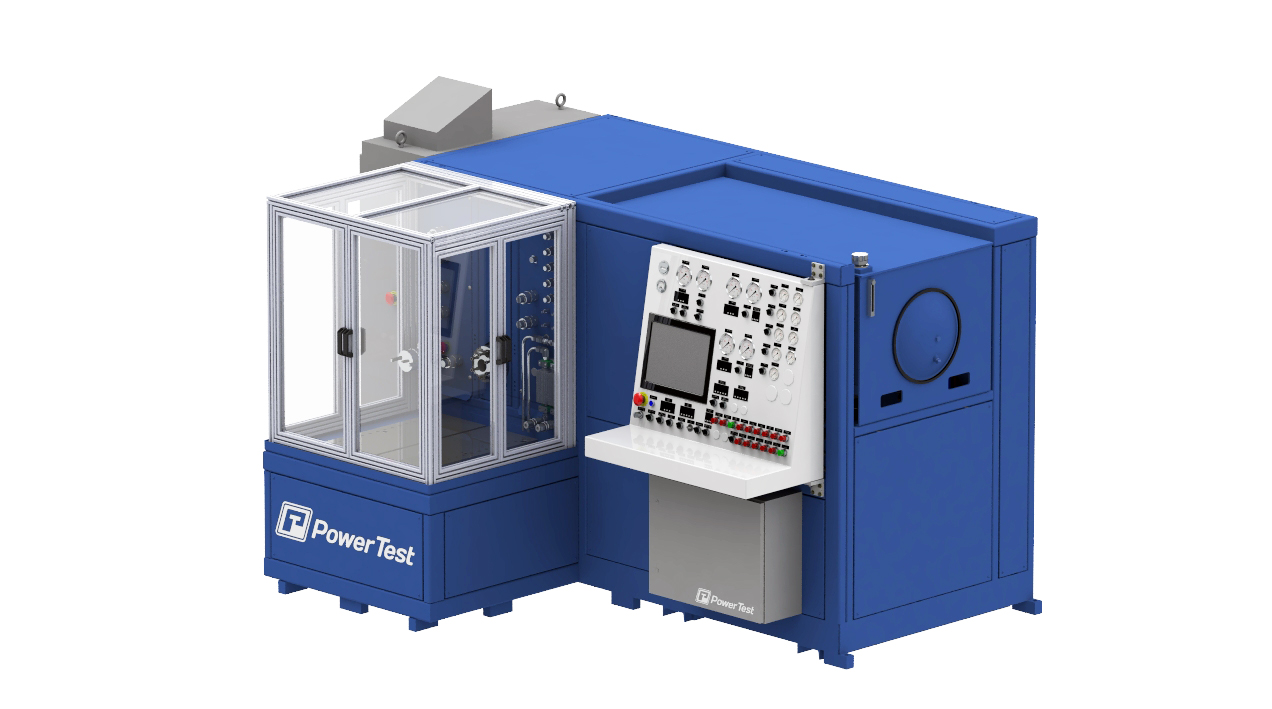

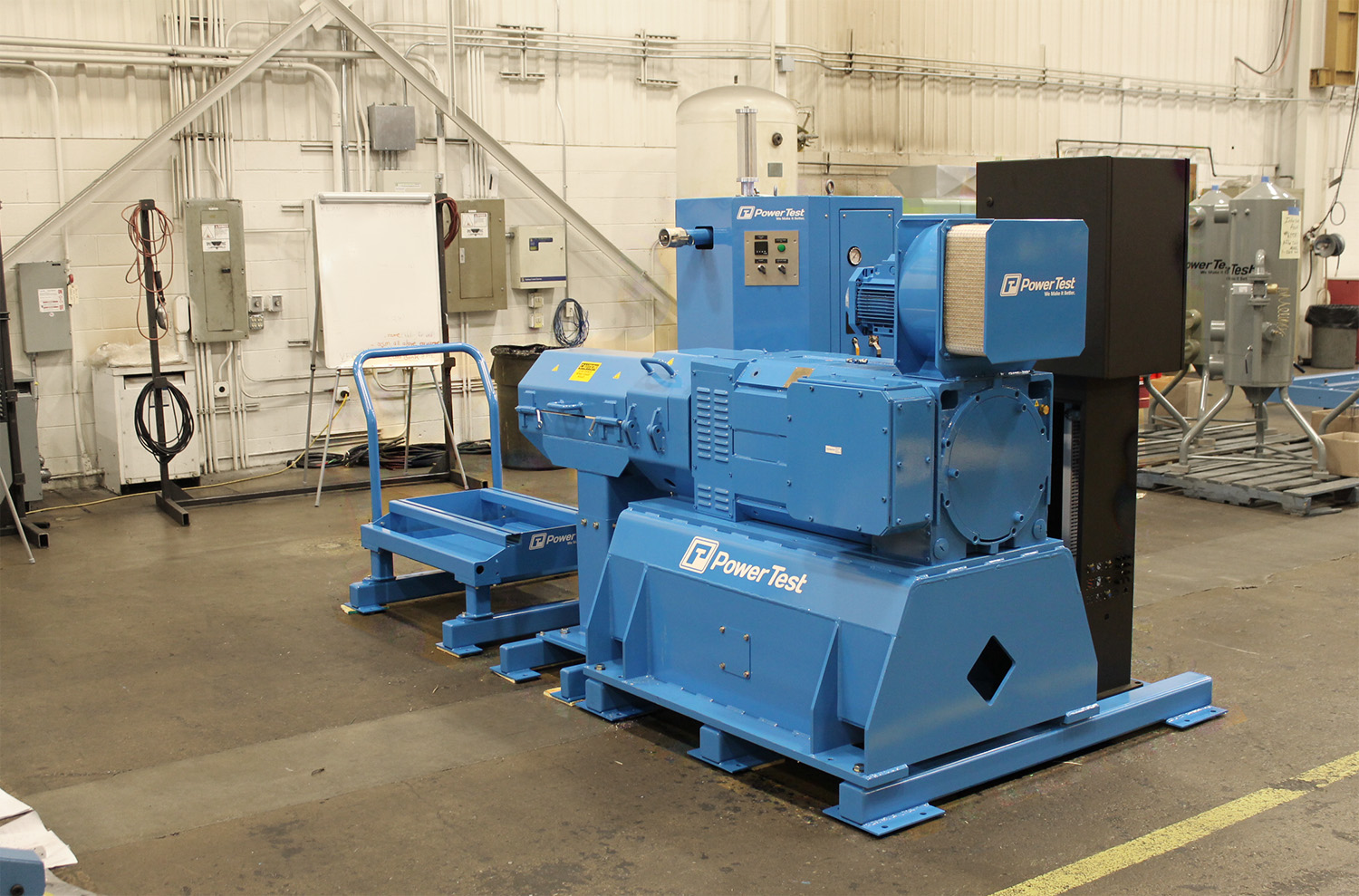

In addition to Power Test’s wide variety of standard equipment, many non-standard powertrain test requirements demand sophisticated engineered solutions.

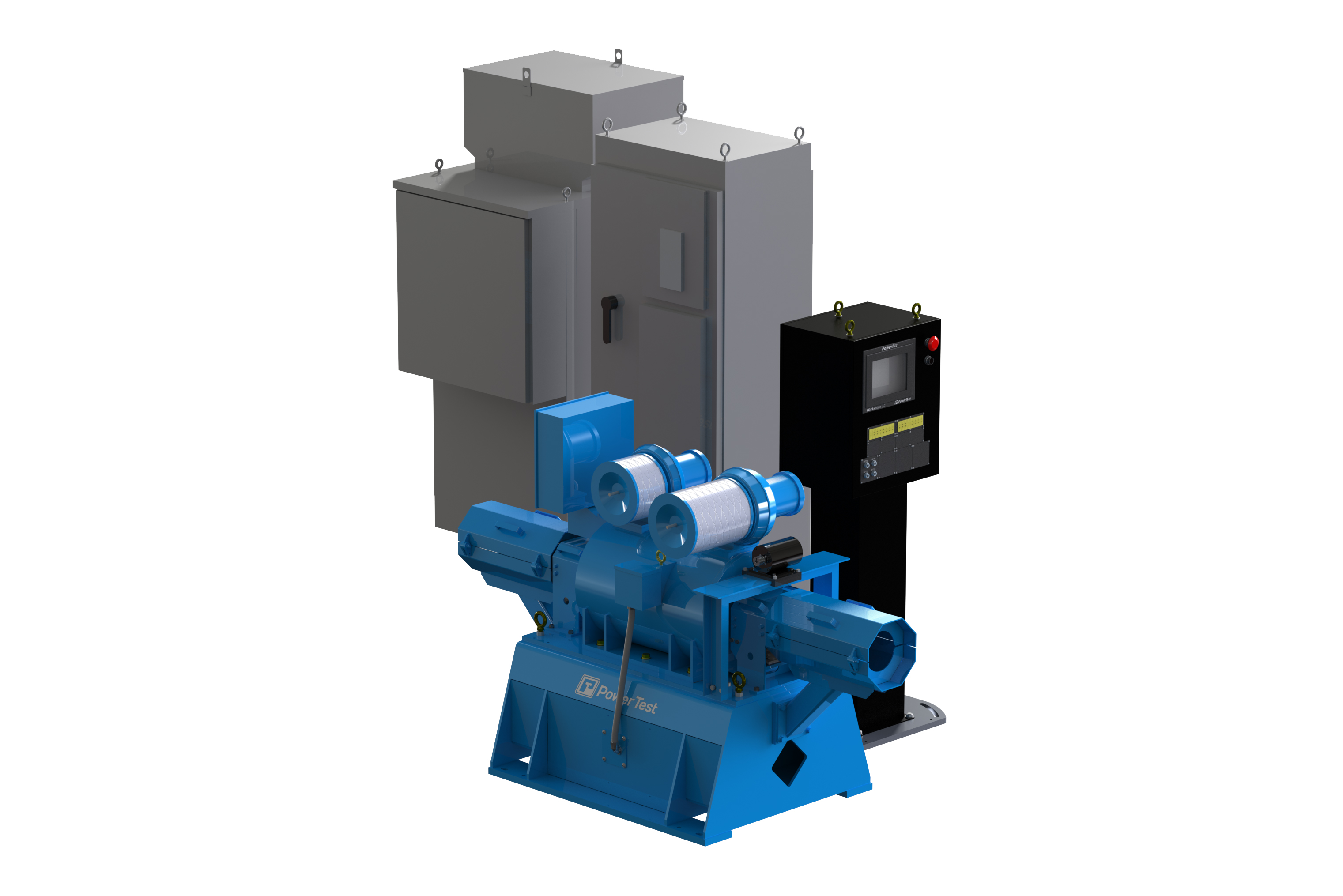

This is why Power Test formed its Custom Engineered Solutions division. This team utilizes Power Test’s industry-leading engineering expertise to create a solution to fit any unique application. The Engineered Solutions team studies all aspects of the test requirement to determine the optimized test solution. The concept is taken by the team of mechanical and electrical engineers to create a new machine design. CAD designers develop solid models of the new test stand for customer review and approval prior to release to our manufacturing operations group, where the testing solution is custom-built.