Dynamometer Water Quality

Maintaining the quality of the water running through your dynamometer is crucial to its longevity. If not regularly checked and maintained, bacteria and algae can build up, which also creates a threat of waterborne illness to your dyno operators.

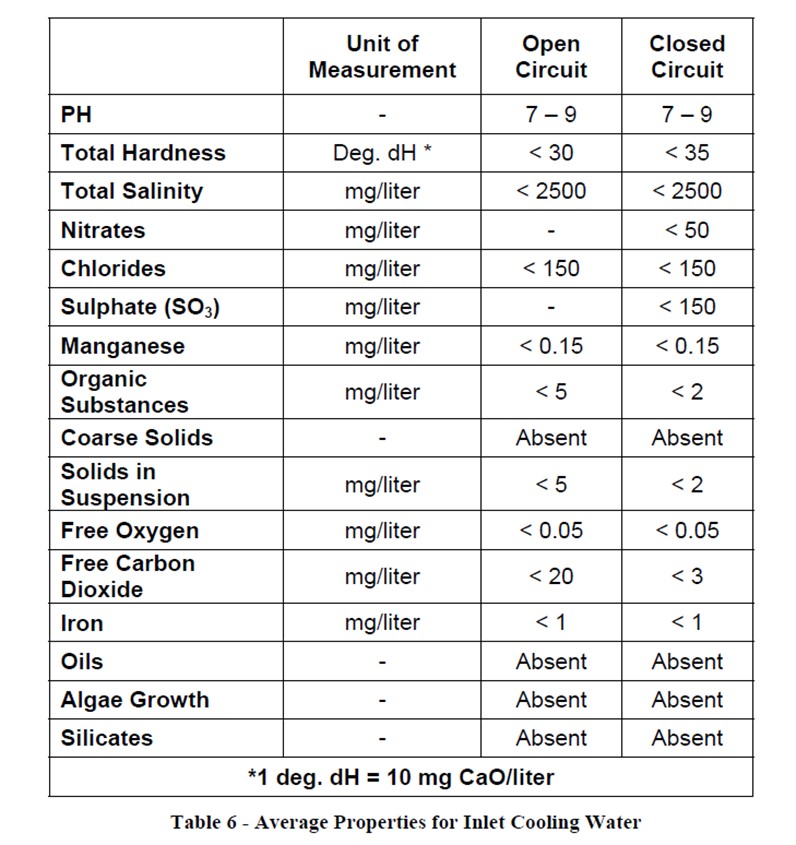

Whether using an open or closed circuit the dynamometer water should meet minimum quality standards. It is recommended to utilize a local water treatment company to maintain the minimum water quality standards noted below.

Average Properties for Inlet Cooling Water

PowerNet (servo) valve systems, additional consideration

Total Hardness: 250 ppm or less.

PH: 7.0 – 8.5

Particulates: 25 micron maximum. Water should be filtered before entering water regulation circuit, if equipped. To monitor filter blockage, water pressure should be monitored before and after filter.

Power Test Non-PowerNet valve systems

Total Hardness: 500 ppm or less.

PH: 7.0 – 8.5

Particulates: 420 micron maximum. Water should be strained using a 40 mesh screen before entering water regulation circuit, if equipped. To monitor strainer blockage, water pressure should be monitored before and after strainer.

Closed (Recirculated) Water Systems

In addition to the above specifications, provisions should be made to prevent the growth of algae and bacteria, so as to prevent the spread of water born disease. If local tap water achieves the minimum water quality specifications, a bleed-off circuit should be able to maintain the water quality. The cooling tower system should bleed-off water at a rate equal to that which will be lost to evaporation from the tower (generally 1% of cooling tower flow rating).

Open Water Systems

If local tap water does not meet the above water quality specifications, consult a water system specialist.