Interstate Power Systems installs new dynamometers from Power Test 40 years after purchasing first unit

Reproduced with permission from the July 2017 issue of Diesel Progress.

[vc_single_image image=”4084″ img_size=”medium” alignment=”center” onclick=”custom_link” img_link_target=”_blank” link=”https://powertestdyno.com/wp-content/uploads/sites/2/2017/07/diesel-progress-article.pdf”][vc_row][vc_column][vc_separator][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Interstate PowerSystems is an authorized distributor for Detroit Diesel, Deutz, MTU, Perkins and Mercedes- Benz on- and off-highway diesel engines, Allison transmissions and a number of other engine-related manufacturers. The company recently completed its move into a new 95,000 sq.ft. headquarters facility in Lakeville, Minn., that replaces a 40-year-old facility in Bloomington, Minn., and consolidates the operations from three separate buildings into a single, more efficient structure.

“We are a people-focused company and the new facility will be home for 50 technicians, 10 parts professionals and the managers and administrators who complete our customer service team,” said Interstate PowerSystems President Michael Masters. “Their efforts are supported by a fleet of 16 field service vehicles and a more than $2.2 million spare parts inventory.”

The new headquarters is as modern as possible in nearly every respect — in-floor heating, a warranty headquarters for the 20-location chain, a training center and a parts and service center with brand new engine, chassis and transmission dynamometers. The dynamometers, supplied by Power Test, Inc. Sussex, Wis., are the latest episode in a business relationship that has been ongoing for more than 40 years.

“The engine dyno in the old facility is a Power Test with Serial No. 0001 that was installed in 1976,” Masters said. “It’s been running reliably for more than 40 years with just normal maintenance. That experience is a major reason why we purchased the dynos for our new facility from Power Test.”

“It’s pretty unusual for a customer to purchase a chassis dyno, an engine dyno and a transmission test stand/dyno all at once,” said Pat Koppa, president of Power Test. “Everyone involved in the job was really proud when the two truckloads of equipment rolled out of our plant on the way to Lakeville.”

The Lakeville service center handles repair and rebuild operations for Interstate customers who cover essentially the full range of diesel equipment users in construction, mining, energy production, power generation, long-haul and local trucking and public transportation. The three new Power Test dynos will support both rebuilt and in-vehicle engine and transmission repair operations.

Interstate PowerSystems has installed new engine and chassis test equipment into its new 95,000 sq.ft. headquarters facility in Lakeville, Minn. Among the new machines is a Power Test 45×07 water brake dynamometer that can handle engines up to 3150 hp as is one of the three highest capacity dynos in the

Interstate network.

“We use the engine and chassis dyno to confirm that a rebuild is producing the specified horsepower and the transmission test stand/dyno to verify operational characteristics like shift points, fluid pressures and operating temperatures,” Interstate Vice President Chris Dacus said. “Having all three allows us to handle just about any vehicle, gen-set or stationary engine any of our customers may be using.”

The new chassis dyno is a Power Test CF22EC4 eddy current unit that can accommodate vehicle drivetrains up to 650 hp. The dyno system is configured as a “backup” cell.

“The backup configuration lets us handle vehicles of virtually any length,” Dacus said. “We will now be able to test things like transit buses that would not fit on our current drive-through dyno installation in Bloomington.”

The only real difference between the two configurations is how the vehicle enters the dyno cell, Koppa said. “A drive-through is a little simpler — the vehicle just drives over the dyno rollers and is then chained down for the test. Once it’s finished the vehicle simply drives away.

“In the back-in configuration, the vehicle literally backs in to the cell. So long as you can leave the door open when necessary and there is no limit to the length of vehicle that can be handled. Of course, you have to lock the rollers and our dynos include pneumatic brakes.

“The choice is really more about building configuration than the dyno installation. Most buildings have back-to-back bays and a drive-through installation uses the floor space of both. In a backup, only one bay is needed, so the other can be used for a shop or other revenue-generating application.”

“A lot of repair work for on-highway vehicles is done without removing the engine from the chassis,” Dacus said. “A chassis dyno is the only practical way to test and verify a repair done that way, so this unit will be used virtually every day.”

One advantage to the CF22EC4 eddy current chassis dyno, Koppa said, was that being air-cooled, “it requires much less maintenance.”

“In fact, our service parts records show that the average annual maintenance cost for one of our eddy current systems is about $461 per year,” he said. “On the other hand, eddy current dynos are limited in the amount of horsepower they can handle. That’s not a problem for a chassis dyno, but it can be for an engine dyno which is one reason water brake technology is still the standard for that application.”

For engine rebuilds or outside-the-chassis repairs, Interstate will use a Power Test 45×07 water brake dynamometer that can handle engines up to 3150 hp. It is among the largest engine dynos in the Interstate network, surpassed only by a 3600 hp unit in Iron Mountain, Mich., and a 4000 hp machine in Gillette, Wyo.

“It’s a very simple, robust system that has proven itself over the years, including our good old Serial No. 1 here at Interstate,” Koppa said of the water brake dyno.

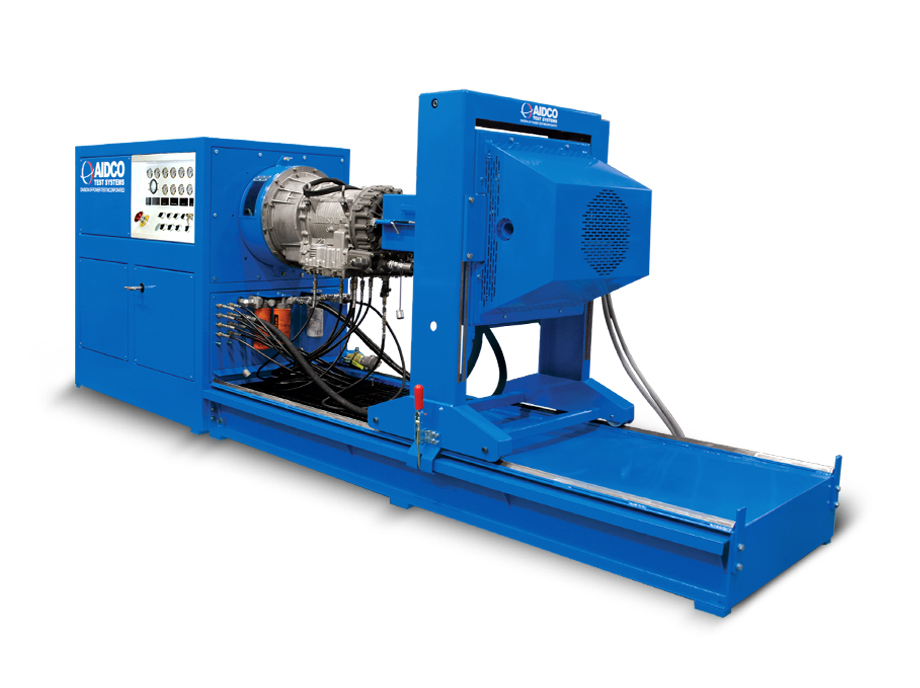

The other Power Test unit installed in Interstate’s new facility is an AIDCO 450E automatic transmission test stand that incorporates an electric motor input drive and eddy current technology for output loading.

Power Test also supplied INterstate with an AIDCO 450E automatic transmission test stand that can be used to test gearboxes as large as Allison’s 800 hp-capable 4000 Series transmission, as well as a broad range of automated manual transmissions used in heavy-duty trucks.

“We call it a test stand, but it’s really a dyno with additional instrumentation,” Koppa said. “It loads the transmission with an eddy current system and then measures shift points, fluid pressure and fluid temperature under load.”

“The Aidco 450E will handle Allison transmissions up to the 4000 Series,” Dacus said. “It’s also fully capable of testing AMT-variant automated manual transmissions which are installed in over 60% of Class 8 trucks being sold today. So we can test virtually any transmission found on an on-highway truck today making it an extremely versatile machine.”

The existing dynamometers at Interstate’s Bloomington facility will probably be moved to other branch location once the new service center is in full operation later this year. All except for the Power Test engine dyno with Serial No. 0001.

“Power Test said they would like to have that dyno back and we agreed to let them buy it back,” Masters said. “After more than 40 years of continuous service it will go home to be exhibited in their showroom.

“Who knows? Maybe in 40 more years these new units can join it.”[/vc_column_text][/vc_column][/vc_row]