AC Regenerative Solutions

From the Custom Engineered Solutions division at Power Test, learn about different braking technology featured in our dynos and see if an AC Regenerative Solution may be right for you.

Rob Kazmier will explore, in depth, a number of topics including AC Regenerative Technology, Applications for AC Regen, and Technological Decision Factors. He will also answer any questions you might have in this conversational and consultative webinar.

AC Regenerative Solutions

Power Test is proud of it’s wide variety of standard products. From Chassis Dynos to 10,000HP engine dynos, and everything in between, we have the experience and engineering expertise to deliver on your testing challenges. Our standard offerings serve industries including construction, oil and gas, transportation, military, marine, mining, and high performance racing, and have delivered results for over 40 years.

But what happens when you’re challenge needs more than a cookie cutter solution? In instances such as these, Power Test Custom Engineered Solutions is ready to take your call. This division aims to identify and solve non-standard problems before delivering custom equipment built to address each and every need for the customer. Our catalog of examples should give you a good scope of projects where we’ve delivered exceptional results.

One of the more profound challenges what we face, is the need to effectively manage the energy involved in a test. We’ve found that AC Regenerative Technology is an exceptional means to accomplish cost-effective, green, and efficient testing for such circumstances.

In this webinar, our Lead Engineer of the Custom Engineered Solutions Division will walk you through the different types of common testing technologies, give you a synopsis of AC Regenerative Technology and identify some of the key applications of AC Regen.

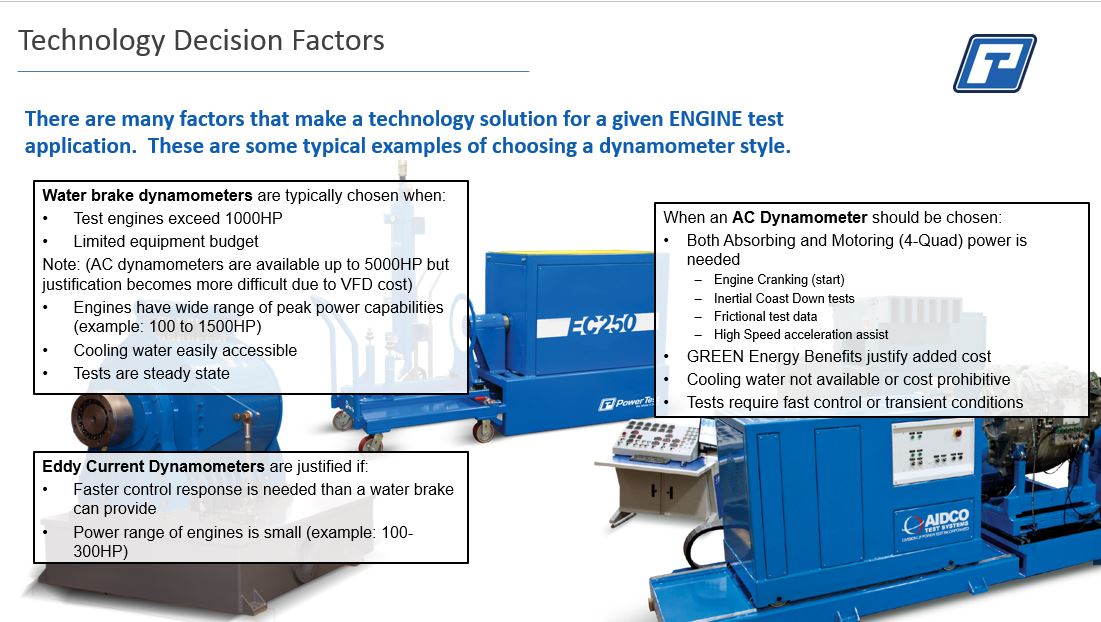

Different Braking Technologies

The most common braking technology used in Power Test dynamometers is a water brake. Water brake systems use water momentum transform, or shearing, to create a load on a rotational component being testing. The absorbed power heats the water, which then must either be cooled, or dumped into the sewer. One of the key differentiators between technologies is how the excess energy is dispersed, which makes the regenerative solution so enticing. Water brake systems can be used in applications as small as an electric motor and are effective in testing engines up to 10,000HP.

Eddy current systems are another common testing technology. Eddy current place a load on an engine under test by inducing a magnetic field in a rotating disc. These systems require electrical input to induce the magnetic field, and generate a fair amount of heat as the rotor spins within the magnetic flux. With eddy current brakes, the excess energy is typically displaced via Air-Cooling systems, somewhat limiting their capacity.

The final piece of technology we explore, is AC Regenerative. In an AC Regenerative system an electric motor serves as both the primary mover and the load which the unit under test is held against. The biggest benefit of such a set-up is that the energy created by the mover, isn’t dissipated as heat. Instead it’s absorbed by the AC motor where it is cleanly put back onto a utilities grid; hence the term Regenerative.