Description

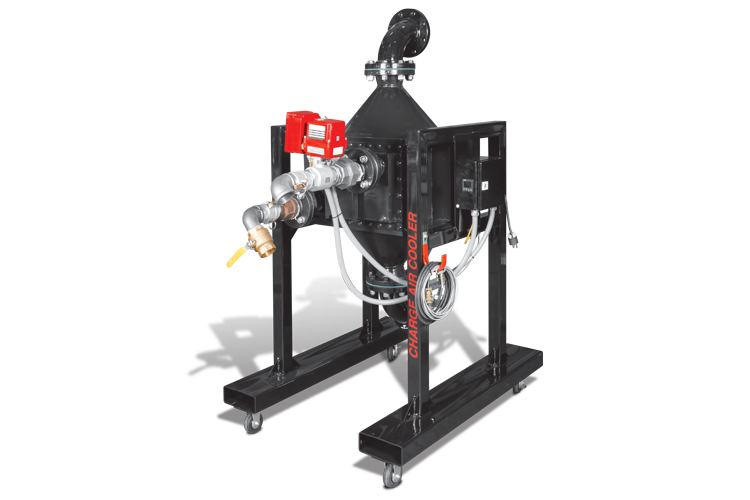

Power Test Charge Air Coolers

Used to replace the vehicular after-cooler for testing air to air after-cooled engines in a test cell. Internal water temperature is maintained through the use of a simple, reliable mechanical control valve. Requires no electrical power. Wall Mounted option available.

Taylor Dyno Charge Air Coolers

Our Taylor Dyno Charge Air Coolers are a temperature controllers with full PID auto tuning. We have versions available in five SCFM sizes: 660, 1987, 2533, 5066, and 5244.

Features

Power Test Charge Air Cooler Features:

- Provides PLC temp. control of charge air outlet to within 15° F (-9° C) of inlet water temp

- Maintains engine inlet air temperatures while testing turbocharged engines

- 50 PSI rated air inlet pressure

- 450° F (232° C) rated air inlet temp

- Requires 35 PSI min. water pressure

- May be used in tandem for higher output applications

- Power requirements:

- Voltage: 120/240 (VAC)

- Amperage: 0.5A

Power Test Wall Mounted Charge Air Cooling System:

- Cools charge air outlet to within 15° F(-9° C) of inlet water temp

- 70 PSI rated air inlet pressure

- 450° F (232° C) rated air inlet temp

- Requires 35 PSI min. water pressure

- Maintains inlet air temperatures while testing turbocharged engines

- May be used in tandem for higher output applications

Taylor Dyno Charge Air Cooler Features:

- Typical Application includes engines rated up to 1,000 hp (746 kW) up to 2,500 hp(1,864 kW) that use air-to-air charge coolers

- 120 VAC or 240 VAC (two versions available)

- Air flow range options from 50 lb/min (22.7 kg/min) to 394 lb/min (178.7 kg/min) mass air flow with a turbo outlet temperature of 450°F (232°C)