Dynamometer Water Supply Pressure and Load Stability

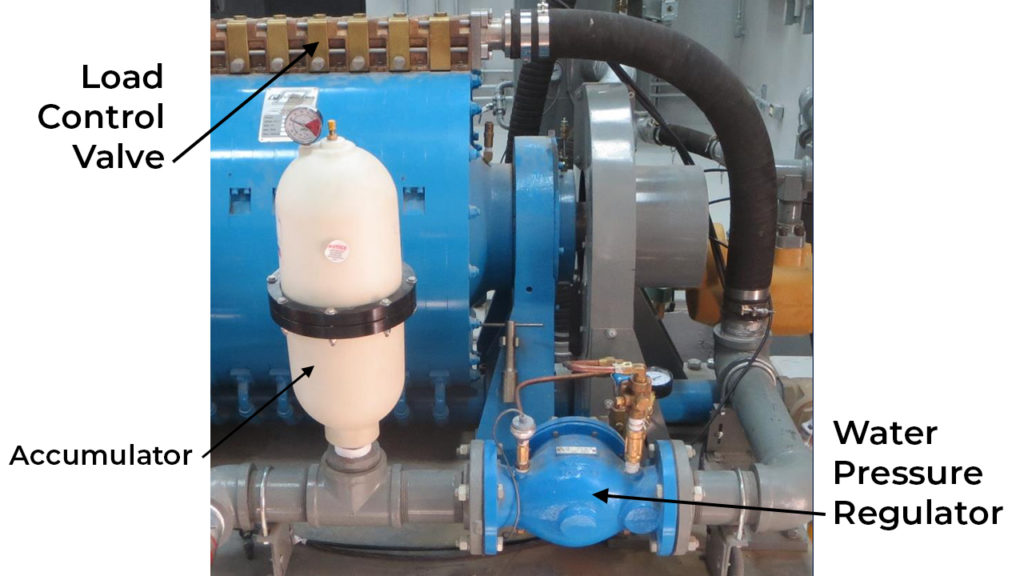

Power Test water brake Engine and Chassis Dynamometers use water as the means of creating a load on the engine or vehicle being tested. A Load Control Valve is used to control the flow of water going into the dynamometer which ultimately regulates the volume of water inside the dynamometer. When the pressure of the water supplied to the Load Control Valve is fluctuating, this will cause the volume of water inside the dynamometer to fluctuate and result in a very unstable load on the engine or vehicle being tested.

A Water Pressure Regulator should be used to reduce the effects of a fluctuating water supply pressure and create a more stable loading condition. The Water Pressure Regulator would commonly be set somewhere between 30psi to 50psi for most Power Test Engine and Chassis Dynamometer applications.

The pressure setting of the Water Pressure Regulator needs to be below the lowest fluctuating point of the water supplied to the regulator. The water supplied to the Water Pressure Regulator should continuously have a pressure greater than 60psi for most applications.

An Accumulator can also be installed before the Water Pressure Regulator to help dampen spikes in the water supply pressure. The air side of the Accumulator should be charged to approximately 80% of the maximum water supply pressure.